You are here: home > Fire Resistant Central Loose Tube Fiber Optic Cables

Fire Resistant Central Loose Tube Fiber Optic Cables

| Place of Origin: | , China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Fire Resistant Central Loose Tube Fiber Optic Cables,Fire Resistant Optic Fiber Cables

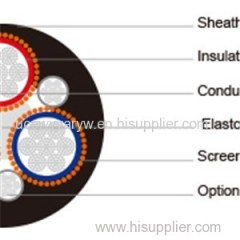

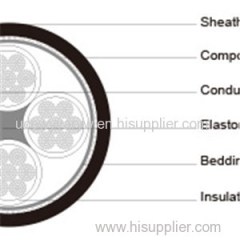

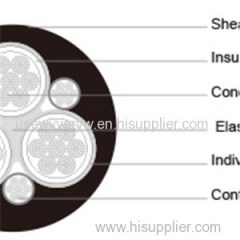

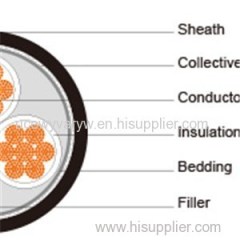

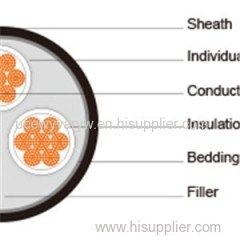

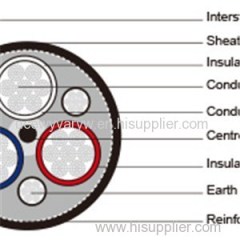

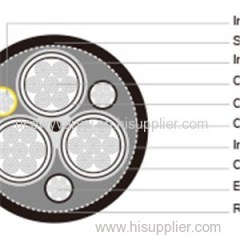

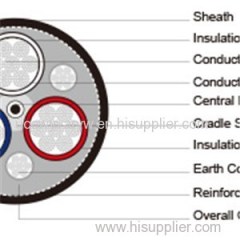

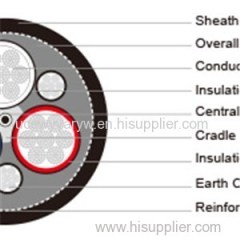

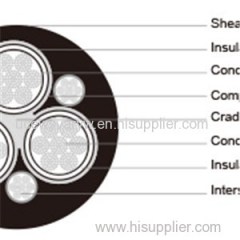

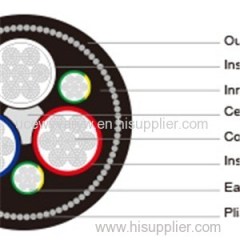

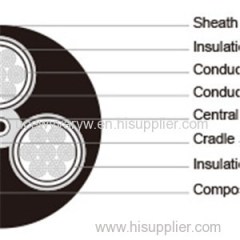

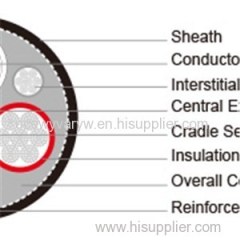

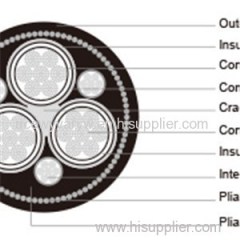

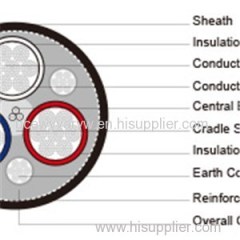

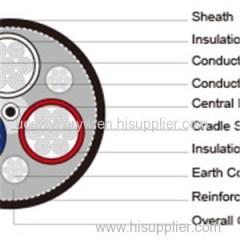

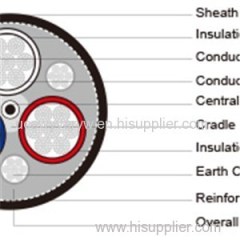

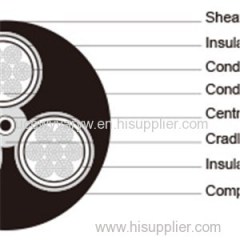

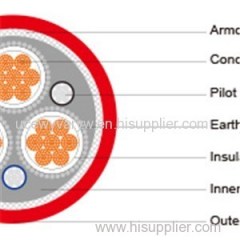

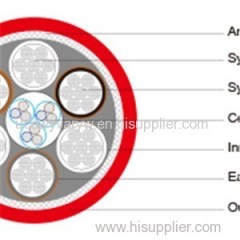

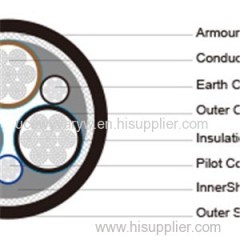

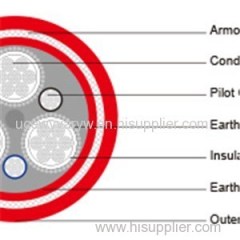

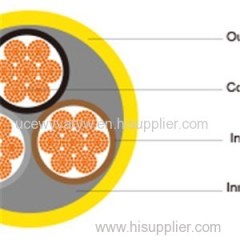

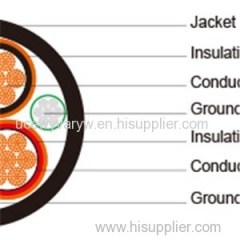

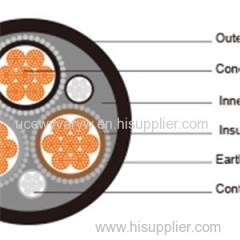

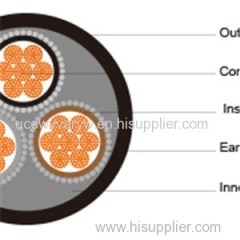

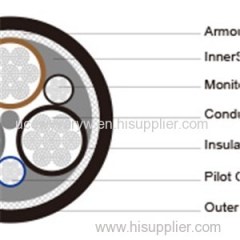

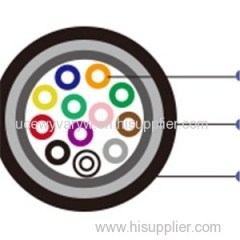

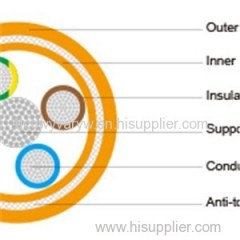

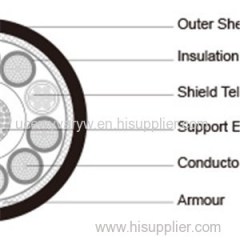

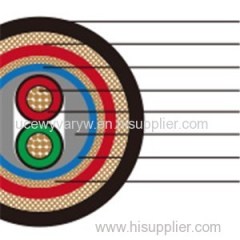

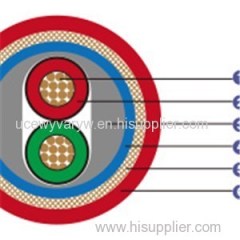

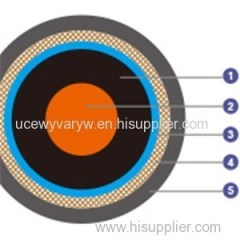

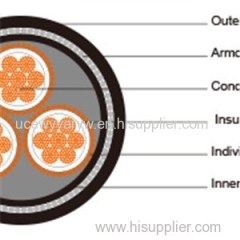

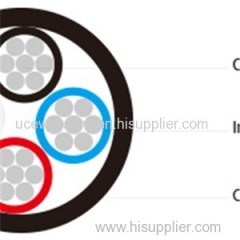

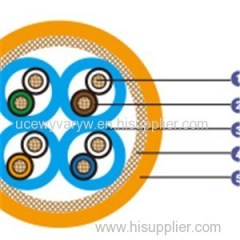

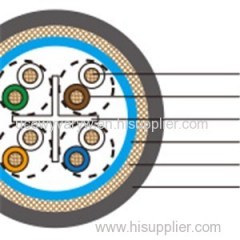

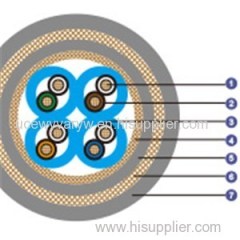

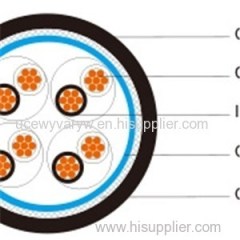

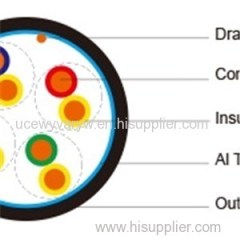

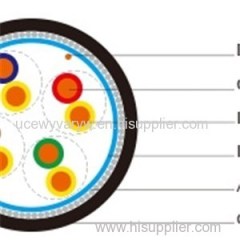

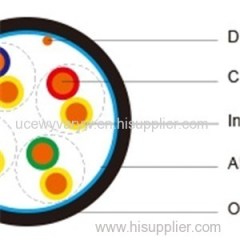

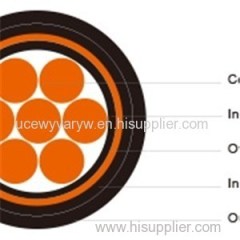

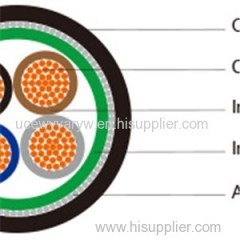

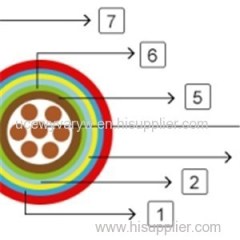

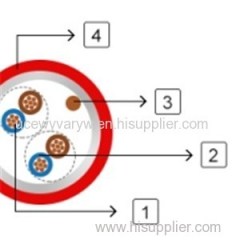

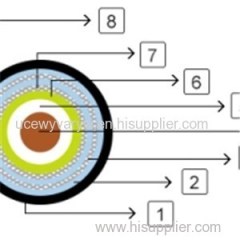

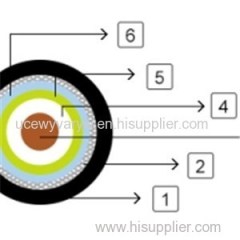

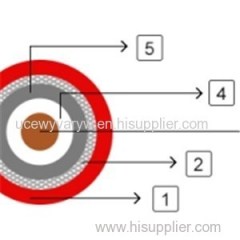

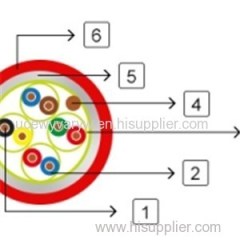

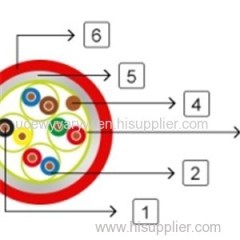

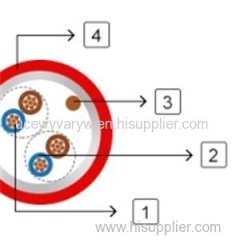

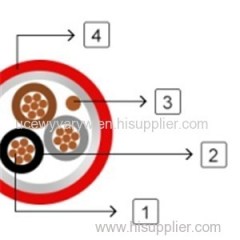

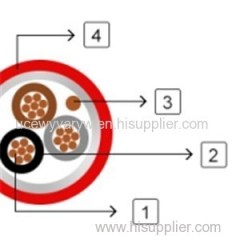

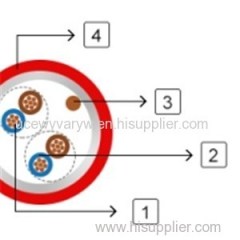

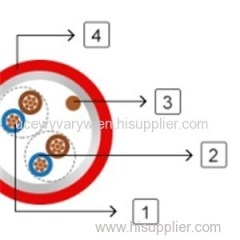

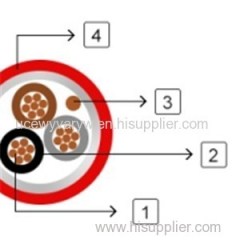

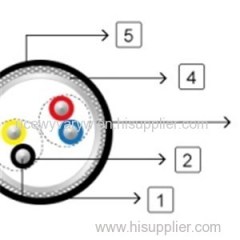

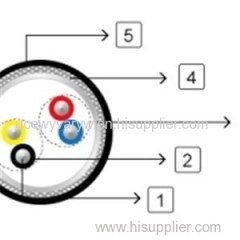

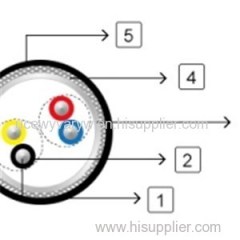

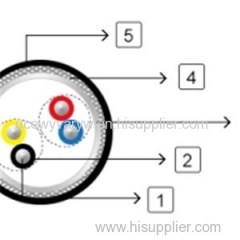

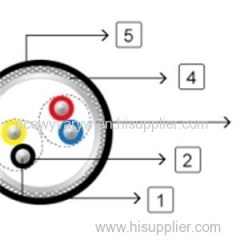

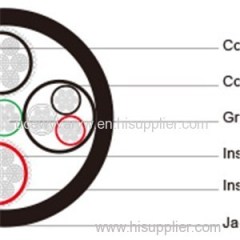

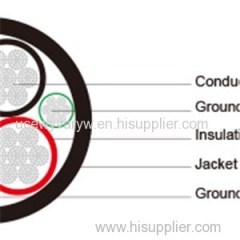

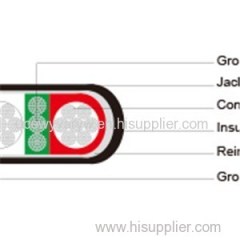

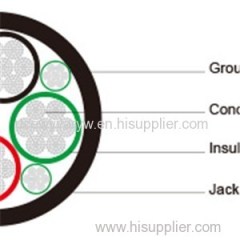

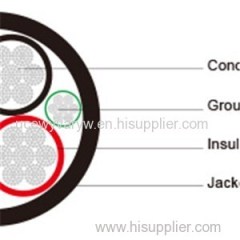

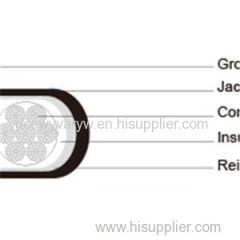

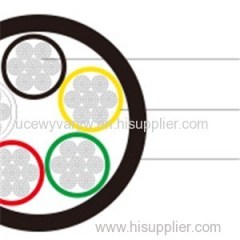

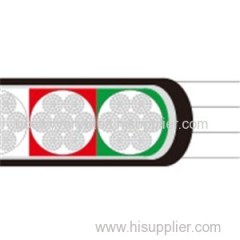

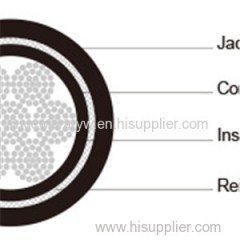

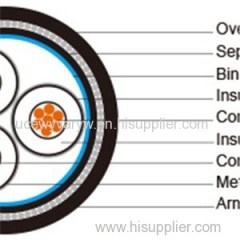

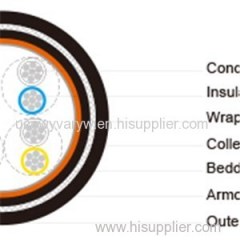

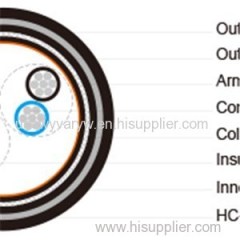

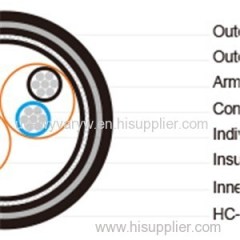

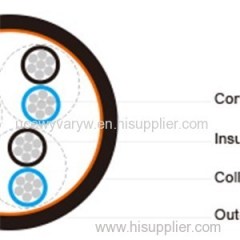

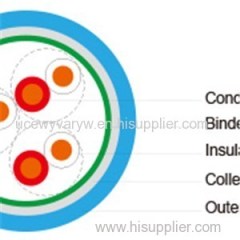

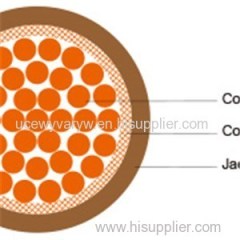

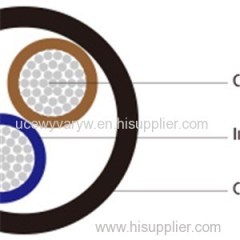

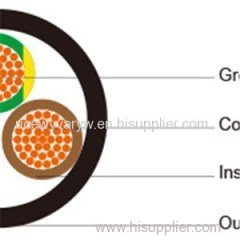

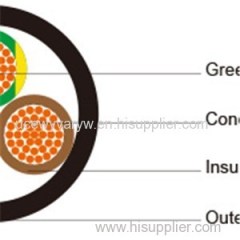

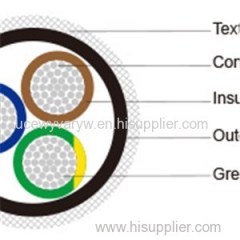

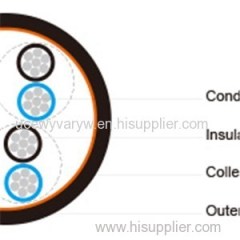

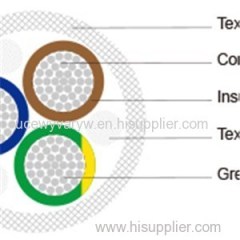

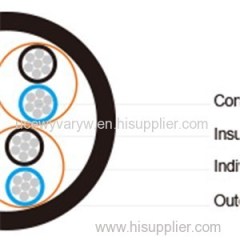

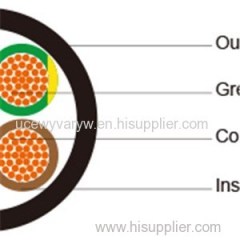

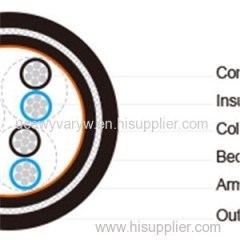

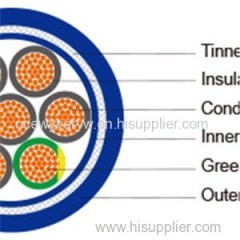

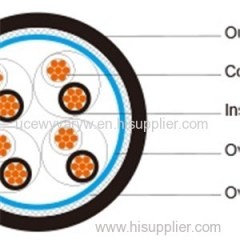

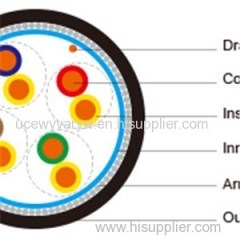

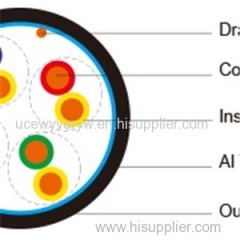

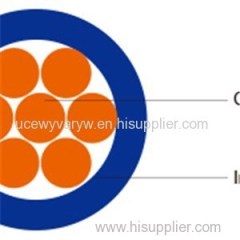

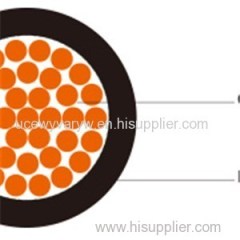

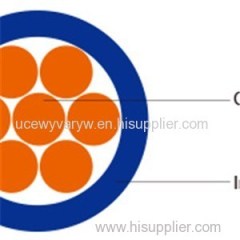

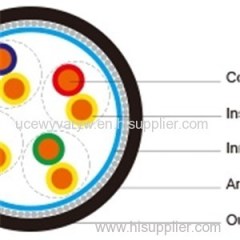

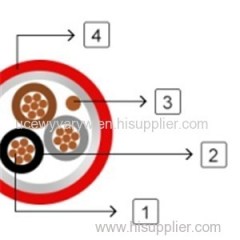

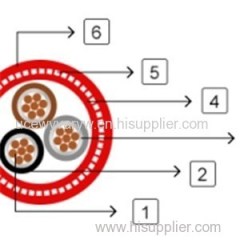

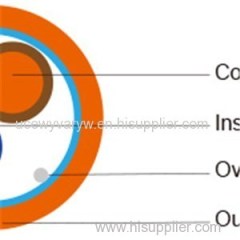

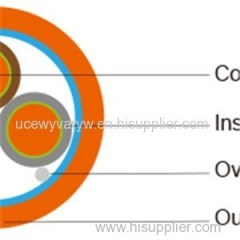

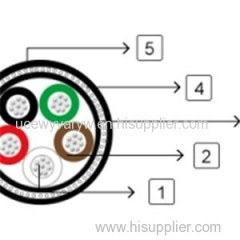

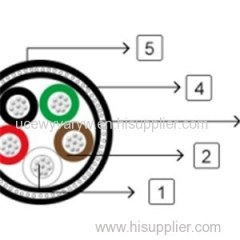

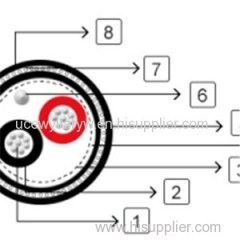

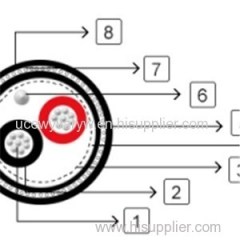

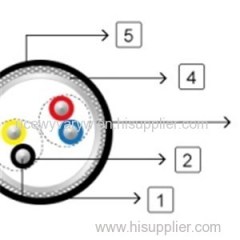

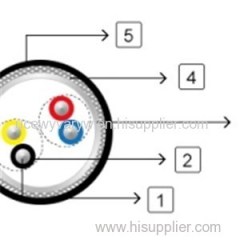

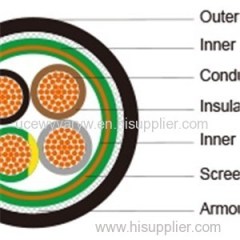

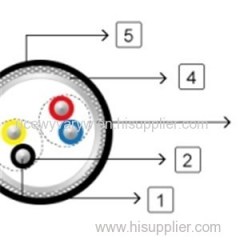

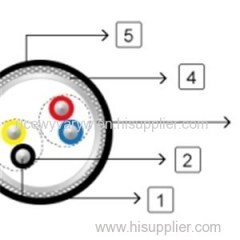

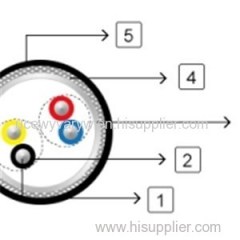

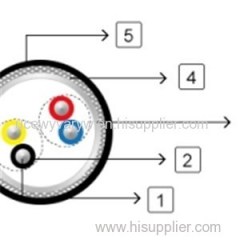

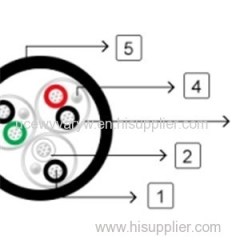

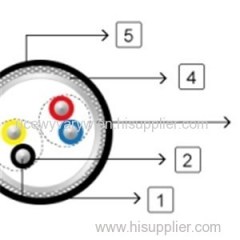

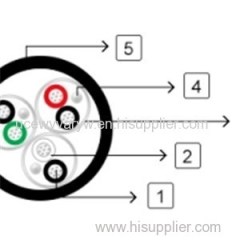

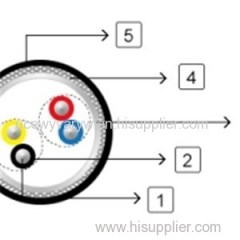

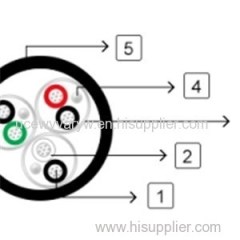

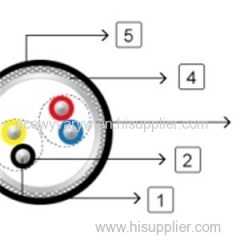

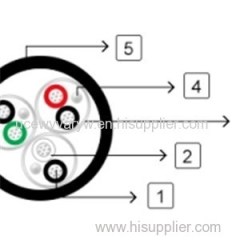

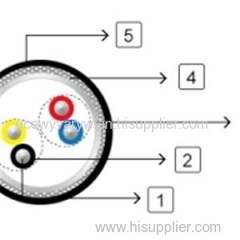

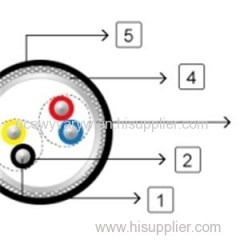

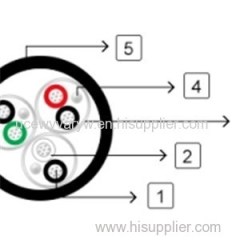

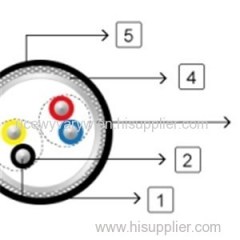

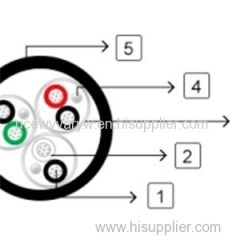

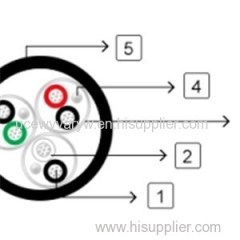

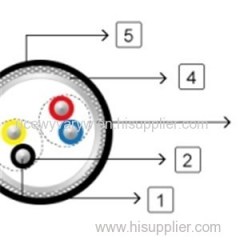

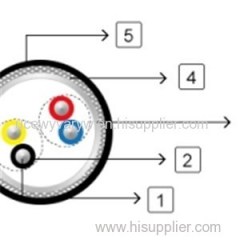

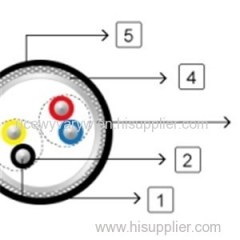

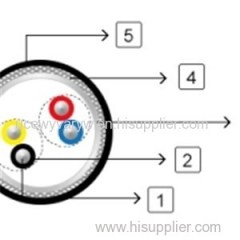

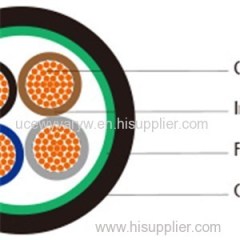

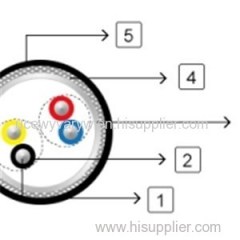

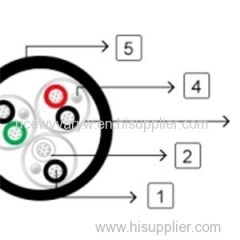

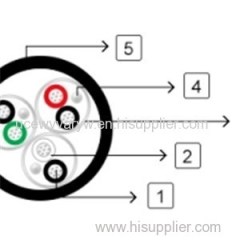

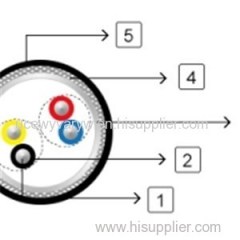

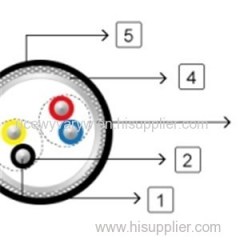

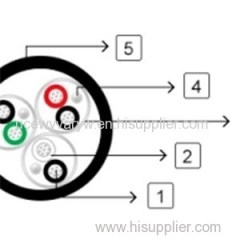

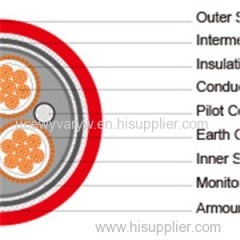

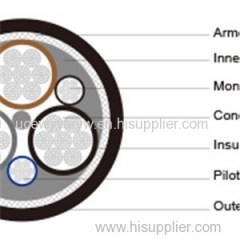

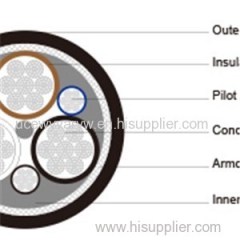

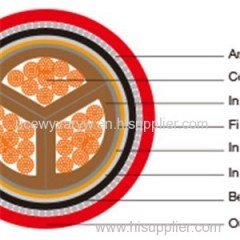

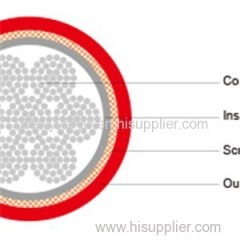

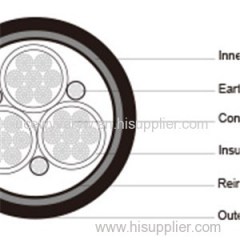

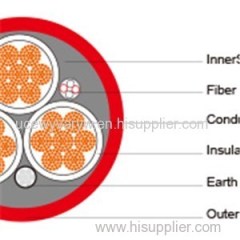

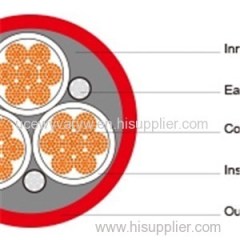

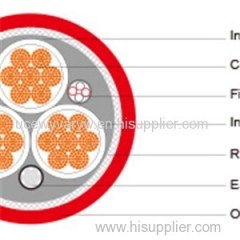

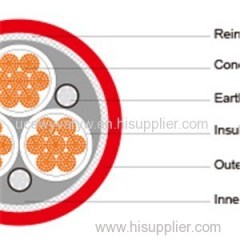

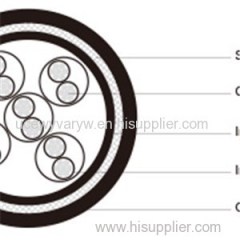

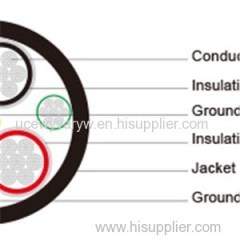

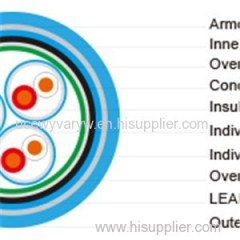

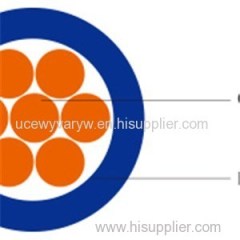

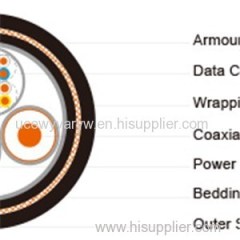

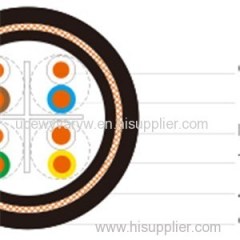

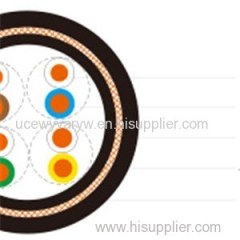

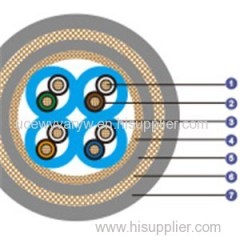

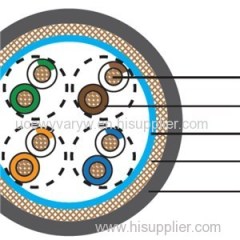

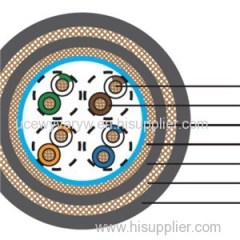

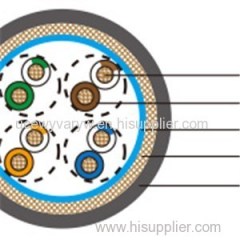

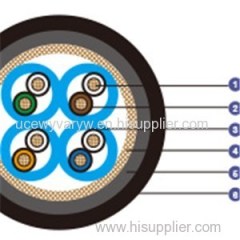

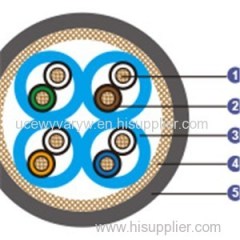

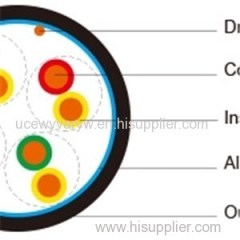

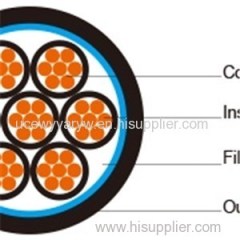

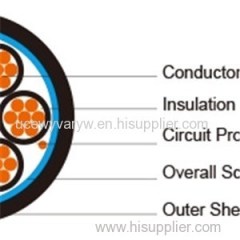

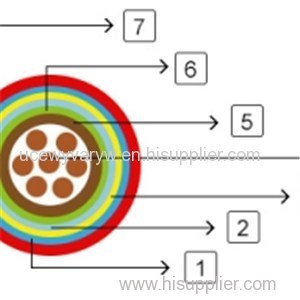

Fire resistant Central Loose Tube Fiber Optic cables FR200P 05M2XSH-R (CU/MICA+XLPE/OS/LSZH 300/500V Class 2 )Application:These cables are characterized by light weight and small diameter,Website:http://www.ue-cable.com, suitable for both aerial and duct installation. They are mainly installed inside buildings, tunnels,subways or closed areas in general, specially designed to guarantee the signal transmission even in case of fire. The cable can also be used for direct burial for armoured versionSTANDARDS:Basic design to Telcordia GR-20 / RUS 7 CFR 1755.900 (REA PE-90) / ICEA S 87-640FIRE PERFORMANCECircuit IntegrityIEC 60331-25; BS 6387 CWZ; DIN VDE 0472-814(FE180);CEI 20-36/2-1; SS229-1; NBN C 30-004 (cat. F3); NF C32-070-2.3(CR1)System circuit integrityDIN 4102-12, E30 depending on lay systemFlame Retardance (Single VerticalWire Test)EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE0482-332-1 ; NBN C 30-004 (cat. F1); NF C32-070-2.1(C2); CEI 20-35/1-2; EN 50265-2-1*; DIN VDE 0482-265-2-1*Reduced Fire Propagation(Vertically-mounted bundled wires& cable test)EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4Halogen FreeIEC 60754-1; EN 50267-2-1; DIN VDE 0482-267-2-1; CEI 20-37/2-1 ; BS 6425-1*No Corrosive Gas EmissionIEC 60754-2; EN 50267-2-2; DIN VDE 0482-267-2-2; CEI 20-37/2-2 ; BS 6425-2*Minimum Smoke EmissionIEC 61034-1&2; EN 61034 -1&2; DIN VDE 0482-1034-1&2; CEI 20-37/3-1&2; EN 50268-1&2*; BS 7622-1&2*No Toxic gasesNES 02-713; NF C 20-454Note: Asterisk * denotes superseded standard.CABLE CONSTRUCTION Fibers: Singlemode and multimode fibers, with loose tube technology.Structure: Central loose tube cable contains one tube with 2-24 single or multimode fibers, whichare filled with water blocking gel.Fire barrier: The jelly filled tube with up to 24 fibers is wrapped with a fire blocking mica glass tapes.Water blocking: The jelly filled tube is waterblocked by using swellable tape and thread.Reinforcement: Either aramid yarn or fiber glass is wound around the tube to provide physicalprotection and tensile strength, with added fire protection.Inner sheath (optional): The cable can be jacketed with either PE or thermoplastic LSZH innersheath. PE is the preferred option in outdoor environment for water protection purpose.Moisture Barrier Tape (optional): An aluminum moisture tape can be incorporated under the sheathfor water blocking and shielding purpose.Armouring(optional):For diect burial, either galvanized steel wire braid, corrugated steel tape armour or galvanizedsteel wire armour is applied over an inner polyethylene or LSZH sheath. For steel tape armour, the0.15mm thick steel tape is coated with a copolymer and applied with an overlap. For steel wire braidor armour, single layer of galvanized steel wire braid or armour is applied.Ripcord (optional): An optional ripcord can be located under the jacket to facilitate jacket removalOuter Sheath: Thermoplastic LSZH compound type LTS3 as per BS 7655-6.1(Thermosetting LSZHcompound type SW2-SW4 as per BS 7655-2.6 can be offered.)Physical AND THERMAL PROPERTIESTemperature range during operation (fixed state): -20°C - +60°CTemperature range during installation (mobile state): 0°C - +50°CMinimum operation Bending Radius: 10 times the outer diameter for unarmoured cables20 times the outer diameter for armoured cablesMinimum Installation Bending Radius: 20 times the outer diameterCONSTRUCTION PARAMETERSCable CodeFiberCountTubeDiameterNominal Overall DiameterApprox.WeightTension loadCrush(n°)mmmmkg/kmNN/100mmCLA-B-C-H-J-FR02-062.78.07010001500CLA-B-C-H-J-FR08-163.59.09012001500CLA-B-C-H-J-FR18-244.210.010015001500Steel Wire BraidCable CodeFiberCountTubeDiameterNominal Overall DiameterApprox.WeightTension loadCrush(n°)mmmmkg/kmNN/100mmCLA-B-C-2Y(SWB)H-J-FR02-062.711.516010002000CLA-B-C-2Y(SWB)H-J-FR08-163.512.018012002000CLA-B-C-2Y(SWB)H-J-FR18-244.213.020015002000Corrugated Steel Tape ArmourCable CodeFiberCountTubeDiameterDiameterApprox.WeightTension loadCrush(n°)mmmmkg/kmNN/100mmCLA-B-C-2Y(STA)H-J-FR02-062.713.020010002500CLA-B-C-2Y(STA)H-J-FR08-163.514.022012002500CLA-B-C-2Y(STA)H-J-FR18-244.214.525015002500Steel Wire armourCable CodeFiberCountTubeDiameterNominal Overall DiameterApprox.WeightTension loadCrush(n°)mmmmkg/kmNN/100mmCLA-B-C-2Y(SWA)H-J-FR02-122.710.518025004000CLA-B-C-2Y(SWA)H-J-FR16-243.511.021025004000mechanical PROPERTIESMaximum Compressive Load4000N for unarmoured cables5000N for armoured cablesRepeated Impact:4.4 N.m (J)Twist (Torsion):180×10 times, 125×ODCyclic Flexing:25 cycles for armoured cables;100 cycles for unarmoured cables.Crush Resistance:263N/cm (150lb/in)Fiber ComplianceTemperature CyclingIEC60794-1-2-F2Tensile StrengthIEC60794-1-2-E1ACrushIEC60794-1-2-E3ImpactIEC60794-1-2-E4Repeated BendingIEC60794-1-2-E6TorsionIEC60794-1-2-E7KinkIEC60794-1-2-E10Cable BendIEC60794-1-2-E11Cool BendIEC60794-1-2-E11

Related Search

Fiber Optic Tube

Loose Tube

Fire Resistant Glass

Fire Resistant Board

Fire Resistant Fabrics

Fire Resistant Pipe

More>>

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

UNIVERSAL CABLES LIMITED [China (Mainland)]

Business Type:Manufacturer

City: Jinan

Province/State: Shandong

Country/Region: China (Mainland)